Going Pro: A series of Thoughts on Becoming a Professional Woodworker

Favorite Vises, Not Vices! Series

The picture makes it look like a Toucan or maybe that is from growing up during the Hippie Generation! It is one of my very favorite vises. Sold as a Pattern Maker’s Vise, Carver’s Vise, Gunstock Vise or even a Luthier’s Vise it is that versatile and more!

I show it here with a sculptured rocker arm clamped between its jaws. How do I select a proper vise?

A vise must clamp the stock so firm that holding the work is not an issue while you attend to sculpting. This vise does just that with two lined jaws that both pivot around most irregular objects (what is a regular object). It also has to be able to hold the work or wood in such a way as to present to the sculptor the work in the proper orientation to the tool and your body position. That is where height and ability to articulate the work between the jaws while repositioning the vise without having to unclamp the work. This vise shines in all of those departments. It has a long screw that makes it mountable in a dog hole on your bench and a large wing nut that makes it possible to spin it around and reposition it. It also gets the work up at a higher level which saves my back. The street price is usually $130 to $180 available online at fine tool retailers. It comes in so many different colors you would think it was sold by QVC, but I think they are all made by the same maker and each retailer sells their own proprietary color. If you want too take a serious step toward something more of a specialty vise, I highly recommend this one!

Where Do I Get My Wood? This is the question I am asked the most by all segments of the population.

For classes I purchase 8/4″ FAS Walnut boards in the rough. I have very little waste and time is money while making the rocker kits ready. I buy from a lumber processor that I trust. Normally I want to go through the boards and select the stock by placing the patterns directly onto the candidate board and vetting it for the part. Buying this way from someone who knows what I want saves time and money and he will not let me pick the pile. I have to buy 5 to 7 hundred board feet at the time and I will happily purchase 6 or 8 ft lengths as opposed to longer. Those lengths fit in a woodshop real well. Longer lengths invoke visions of the Three Stooges moving boards around the shop knocking people and things over! The weight of that much wood is hard to haul in a trailer up the interstate without incurring much stress. I rent a cargo van to make the hauling a breeze. Savings in buying this way is about half the price from buying through your local lumber supplier.

I am always on the lookout for wood sources especially Walnut and Curly Maple. I let people know the species I prefer. You can waste a lot of time looking for wood this way. People think any size Walnut tree that is down will send a relative to college and it is rarely true. I have driven out to see too many logs that should have been firewood, then you have to inform the helpful person that it isn’t going to send Johnny to Harvard. Now I ask for pictures of the tree first.

Worth the Risks to Find Great Stock?

For commissions I want particular grades of wood for different parts most of the time. I love working with figured slabs and quarter sawn boards. Figure or the lack of it can be very important in a piece of furniture. When I hear someone talking about their ancestors’ cache of hardwoods in an old barn, I want to know more. Many times the wood is holding up the barn. I had one such ancient structure fall down slowly as I pulled the 10/4 20″ wide veneer quality cherry boards from the pile. I have also suffered physically from the chigger bites received from fighting the five foot tall grass surrounding a pole barn full of the best wormy, Curly Maple ever.

In Middle Tennessee brown recluse spiders fall off boards by the pounds while shuffling walnut boards in the

darkness of an ancient pole barn. Wood safaris may not be for the faint of heart!

Storage

Storage is a problem if you collect a bunch of wood you don’t need. I am not a pack rat woodworker. Many are pack rats and they have to find places for the packing. Wood storage is many times a problem anyway. It has to be stored correctly, too.

You might enjoy this story about storing a wood shipment.

I got the call and $40K in English Walnut in the form of three slabs at 10/4″x 6 1/2′ x 17′ was headed my way in a sealed container that afternoon. That is great news unless you have a 24’x24′ shop in a subdivision with a Gestapo HOA. I had to quickly remove the glee from my face and come up with a plan for diverting the shipment. My neighbor had a moving and storage business with a forklift. I asked him if he would receive the shipment and he said, Yes! I was there when it arrived and we placed a chain around the slabs and delivered them to an open area with stickers. I used a 10″ Makita circular saw to break them down to workable billets before transporting them home to my shop and the rest to a storage building I rented for this purpose.

... And Then What? The three words I use as a guide for my woodworking and business decisions!

Whatever you are planning to do, try to answer the simple question, “After I have completed the task … And then what? … before taking any further action. If you can’t answer that question, you are not ready to proceed!

I had a student several years ago in my sculpted rocker class who out of the blue made a rogue cut on his back leg on the last day of the class. He had marked everything for the cut perfectly and without thought cut on the wrong side of the back leg. He forgot to ask himself, after I cut here … and then what? We made him another leg, but it is simple to ask yourself the question and not make a fatal mistake.

Woodworking and business are like playing chess. You must think strategically and be able to predict with some certainty what you will do after you cut a dado across your board, or make a purchase for your business. Yes! This can be termed differently in a question like, I am going to cut this dado to what end? But, I like it simply, If I do this … And then what?

Woodworkers are basically problem solvers, they like to explore the … what ifs? But I would add …And then what to the process?

My Story, Again! (I know you wonder why I keep talking about myself)

I had a 4×4 utility closet with a water heater in it to work from when I started. I had a vision of a log rack (Jimmy Carter Era) that I wanted to build for myself and purchased my first major tool. It turns out that a lot of woodworkers from my time bought Sears Radial Arm Saws first. It promised a lot but would only cross-cut. That is what I needed, something that would cross-cut. I built the log rack and a mailbox post out of rough sawn Cedar. Neighbors wanted them and finally a local nursery wanted them and I was in business. I had something to make for a profit. I wanted to leave my job as teacher and become a professional woodworker (what a stupid idea).

If you are going to make everything (Be a Woodworking Generalist), that is really scary. You need all the tools and you have no target and no identity and no market. My advice is to pick something that interests you a lot and pursue it, and don’t fill up your shop with a lot of things that don’t fit your plan.

Woodturning is a great thing to get into. Takes less of an investment, you can grow your skills, build a reputation and the investment isn’t so huge as to make you have to build an overhead to feed. I am just saying!

Study what other known professional woodworkers are making. Look at their websites and think how you would design or build that differently. Play in your shop and try things that are out of your current ability range. Make something that will turn a head or two or a whole community.

As many of you know, my woodworking and training as a teacher led me to teach woodworking. That’s what I make ……. I teach woodworkers to reach for the next thing on their journey and provide for some of the help to assist them in their success! The best tools I acquired along the way were patience, persistence and a PENSION (by keeping my day job)!

Are you a businessman, too?

Who are you? Interview yourself. Well, Have a private conversation with someone I hope you like.

Are you an entrepreneur? Do you think about and live the life of one who buys and sells for a profit? Unless you have a family nest egg that can give you the freedom to pursue the life of a creative, then making a living and taking care of responsibilities must be a part of your conversation about becoming a professional woodworker.

I tried it in the early 1980s before the internet, but after the invention of the circular saw. I left a salaried job with a wife and a child, for which I was responsible, and tried to build and sell furniture in a mill town market. Quickly I found myself not able to make a decent profit. The townsfolk were not a profitable target market and I could not reach any further than locals. I was trying to compete with the local Ethan Allan Store and cheap furniture. I started making emotional decisions instead of the decisions of a businessman. Well, Back to my day job (for which I was thankful) ! I could make furniture in the evenings and on the weekend without having a commercial location. Lesson learned!

Many of the master woodworkers I have had on the Highland Woodworker Show are happy, inspired artists. They are not in it for profits just the opportunity to do the next project. Their spouse may have the health insurance and a job that gives them the luxury of being a maker.

Here is my formula for becoming a success as a woodworker. Don’t start out with a commercial shop. Develop a product with a brand and a following from a location that does not require you to bite off an overhead that must be fed dollars. Most successful businesses started in a garage and finally grew financially and physically to the point where they demanded a commercial shop.

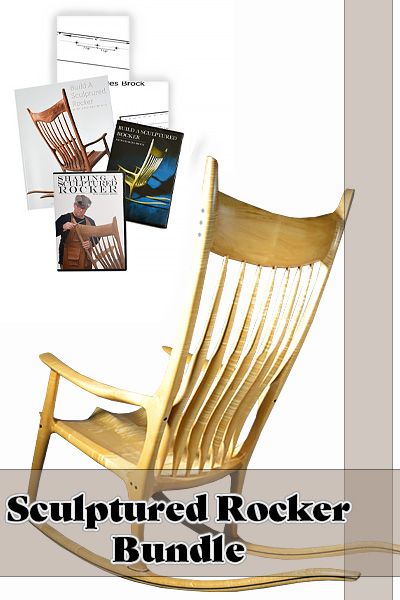

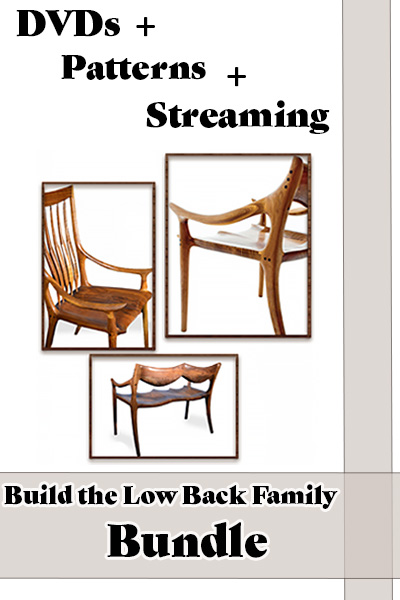

I built furniture in a garage shop (until 2010) and finally taught woodworking in that same garage shop in the suburbs. I wasn’t zoned correctly to do that at all. If you are mindful of your neighbors and do things for them and keep everything tidy they might play along. Finally I had the products selling in the form of rocking chair instructional bundles and had the need to teach hands on classes in a space of my own, so I leased a commercial shop.

Don’t hire anybody you don’t have to have, cause then you are responsible for feeding them and all of the paperwork. Collaborate with people who have talents you need. Bookkeepers, Web developers and everyone who has a talent your business needs can be hired on a limited 1099 basis to do a specific job. You don’t want to build anymore of an overhead than you have to!

Keep your business flexible and always feel an eye on your cash. Buy tools for the job at hand, and make them pay for themselves. Your business will change because you will be redefining your business more consistently than you think!

Getting Attention

Being the yellow glove waving in an infinite sea of white gloves! If you can achieve that for your product or brand you have done something special.

Being the yellow glove waving in an infinite sea of white gloves! If you can achieve that for your product or brand you have done something special.

Everyone is trying to get your attention. You have consumer and personal choices to make every waking hour. What gets your attention? Usually it is something that stands out as being different. In 1983 when I flipped through a new copy of Fine Woodworking Magazine, something caught my eye and I had to go back and find it, read about it, become enamored with it, be consumed by it! In other words, know everything about the rocking chair I saw in the magazine. Why? It was different. All of those hard lines, soft lines, s-curves were something I had not seen in any woodworking composition.

A chair making friend of mine works high end, art shows in the US. He said it was imperative to have something new and engaging that would snap the customers head around to be noticed at the show. His sales depended on it! He came up with something very novel that included suspending articulating chair parts! It even sounds interesting doesn’t it? He is delivering chairs sold all over the US to clients who pay him well!

I am different in that I specialize in teaching a chair design that has been in heavy demand for over a decade.

What will you do to be that yellow glove that is quickly noticed without breaking the laws of good taste in design? Or maybe you can redefine taste and design!

Who is going to buy a $10K Rocking Chair?

I was traveling before six in the morning recently, on my way to do a personal appearance at a Lie-Nielsen Tool Event. There was a big chance that I would hit snow driving north in the early hours. Why was I up I asked myself. Why was I driving into who knows what? As dawn broke, I saw other people, grim faced, headed to work. This caused me to think about some of the other jobs to which I had trudged, day after day, five days a week. Who do I have to answer to now? What makes me do this? Is it worthwhile?

On 11 AM on Christmas Day past, celebration was interrupted with loading a rocker into an SUV to make a delivery to a local bank president’s family. I had worked nonstop for two to three weeks to finish the rocker as a Christmas present from a father to a daughter’s family. Everybody else was Christmas shopping, wrapping presents, cooking Christmas goodies, but I was in the shop with rasps, scrapers and sandpaper in hand. The muscle memory is easy when you are constantly moving your hand and arm back and forth, back and forth, forth and back, on and on. Why? Why? Why? When I finish this rocker, fortunately I get to craft another one and do this all over again!

My hands have grown gloves. They are rough. They are a purple-lish brown all the time from the walnut. I’ve got a scar running across my palm and an index finger that always feels like it has an electrical current running through it as a reminder of what can happen while working half asleep.

It’s all about your point of view at the time. You have to be able see the big picture, understand what motivates you, knowing that nothing worthwhile comes without sacrifice, and that the possibility to achieve only comes when we complete the drill. You also have to work hard at the task at hand, be it sanding, measuring, coming up with a work around, paying the bills, working on the website or planning to connect with someone with enough money and interest to pay you to build one.

Sounds like a great life! Huh? It is not for everybody. I am not an overnight success with the DVD bundle. A good friend explained it to me recently. “You learned your trade one success and one failure at a time for thirty years building furniture. You worked your plan to finish raising a family as a full-time educator while you worked nights building furniture commissions for clients. You retired from one career at the same time you finished the DVD, book and pattern bundle to go with teaching sculptured rocker making at Highland Woodworking. You paid your dues many times over. You finished the drill!”

Sam Maloof told hundreds of woodworkers and want-to-be pros at his workshops that with all his talent, making a living was hard. He said the mailman would eagerly celebrate with him with the coming of a check and despair at delivering the bills. If you have mouths to feed it all becomes real very fast. You have to have support. Meaning there has got to be someone willing to carry your water while you work your plan.

Can you finish the drill? The next post will explain why finishing the drill can be worth it to you.